No powertrain DTCs or freeze: a puzzling diagnostic scenario that challenges the limits of automotive troubleshooting. This enigmatic condition, characterized by the absence of fault codes and freeze frame data, demands a meticulous approach and an in-depth understanding of vehicle systems.

Delving into the intricacies of powertrain diagnostics, we’ll uncover the significance of DTCs and freeze frame data, shedding light on their role in identifying and resolving vehicle issues. By exploring the causes and symptoms of no powertrain DTCs or freeze, we’ll equip you with the knowledge and strategies to tackle this diagnostic conundrum.

Powertrain DTCs Overview

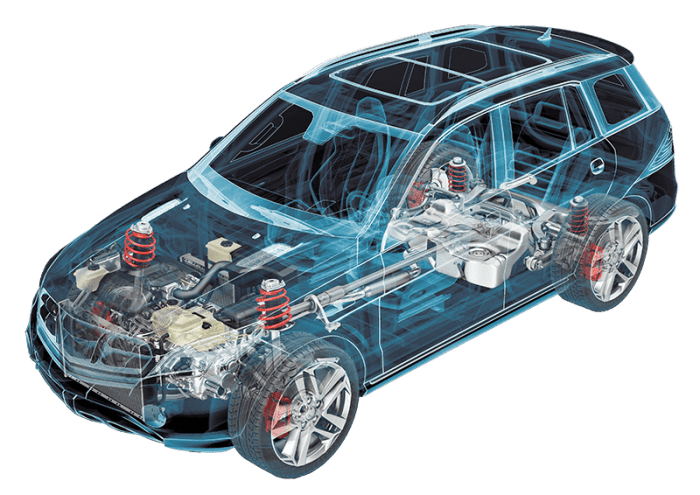

Powertrain Diagnostic Trouble Codes (DTCs) are diagnostic codes specifically related to the powertrain system of a vehicle. They provide valuable insights into potential issues or malfunctions within the engine, transmission, driveline, and other powertrain components.

Powertrain DTCs play a crucial role in vehicle diagnostics. By retrieving and interpreting these codes, technicians can quickly identify potential problems and pinpoint the affected components. This enables them to make informed decisions regarding necessary repairs and maintenance, ultimately ensuring the optimal performance and longevity of the vehicle.

Potential Causes of Powertrain DTCs

The potential causes of powertrain DTCs are diverse and can vary depending on the specific code and vehicle model. However, some common causes include:

- Sensor malfunctions

- Electrical issues

- Mechanical problems (e.g., worn components, fluid leaks)

- Software bugs or glitches

- Environmental factors (e.g., extreme temperatures, moisture)

Freeze Frame Data

Freeze frame data is a snapshot of the vehicle’s operating conditions at the moment a powertrain diagnostic trouble code (DTC) is set. It captures a wealth of information, including engine speed, load, fuel trim, and other parameters, that can help technicians pinpoint the root cause of the issue.

When a DTC is set, the vehicle’s powertrain control module (PCM) records a freeze frame of the engine’s operating conditions at that instant. This data is stored in the PCM’s memory and can be retrieved using a scan tool.

Importance of Freeze Frame Data

Freeze frame data is an invaluable tool for diagnosing powertrain issues because it provides a detailed snapshot of the engine’s operating conditions at the moment the DTC was set. This information can help technicians:

- Identify the specific operating conditions that triggered the DTC

- Rule out intermittent problems that may not be present during a road test

- Compare freeze frame data from different DTCs to identify common factors that may be contributing to the issue

Troubleshooting No Powertrain DTCs or Freeze Frame

When a vehicle exhibits drivability or performance issues but no powertrain diagnostic trouble codes (DTCs) or freeze frame data are present, it can be challenging to pinpoint the cause. This condition can indicate various potential issues, and a systematic troubleshooting approach is necessary to identify and resolve the problem.

Possible Causes

The absence of powertrain DTCs or freeze frame data can be caused by several factors, including:

- Intermittent or transient faults that do not trigger DTC storage

- Sensor or wiring issues that prevent accurate data collection

- Control module malfunction or software errors

- Mechanical issues that do not generate electronic codes or freeze frame data

Troubleshooting Steps, No powertrain dtcs or freeze

To troubleshoot this condition, follow these steps:

- Verify the symptoms and observe the vehicle’s behavior under different driving conditions to gather more information.

- Inspect the wiring harness and connectors for any damage or loose connections that may affect sensor or control module communication.

- Use a scan tool to monitor live data and observe sensor readings and control module parameters while the vehicle is running.

- If live data indicates sensor or control module issues, further diagnose and replace the faulty components as necessary.

- Consider mechanical inspections, such as compression tests, fuel pressure checks, or vacuum readings, to identify potential mechanical problems that may not generate electronic codes.

Advanced Diagnostics

When no powertrain DTCs or freeze frame data are available, advanced diagnostic techniques are necessary to identify the root cause of the issue. These techniques involve using specialized tools and equipment, such as scan tools, oscilloscopes, and pressure gauges, to analyze vehicle data and pinpoint the source of the problem.

With no powertrain DTCs or freeze frames to indicate any issues, the vehicle’s performance remains a mystery. The enigmatic nature of this situation is akin to the conflict of the scarlet ibis , where the struggle for survival unfolds in an equally puzzling and captivating manner.

However, like the ibis’s resilience in the face of adversity, we persist in our efforts to unravel the secrets hidden within the vehicle’s systems.

Specialized Tools and Equipment

- Scan Tools:Advanced scan tools provide real-time data monitoring, allowing technicians to observe sensor readings, actuator commands, and other vehicle parameters while the vehicle is in operation.

- Oscilloscopes:Oscilloscopes display electrical signals as waveforms, enabling technicians to analyze the timing and amplitude of signals to identify potential electrical faults.

- Pressure Gauges:Pressure gauges measure fluid pressure in various systems, such as fuel, oil, and coolant, helping to diagnose issues related to leaks, restrictions, or pump failures.

Diagnostic Case Studies

Case 1:A vehicle exhibited intermittent stalling but no DTCs or freeze frame data were present. Using an oscilloscope, the technician analyzed the crankshaft position sensor signal and identified an intermittent drop in voltage, indicating a faulty sensor.

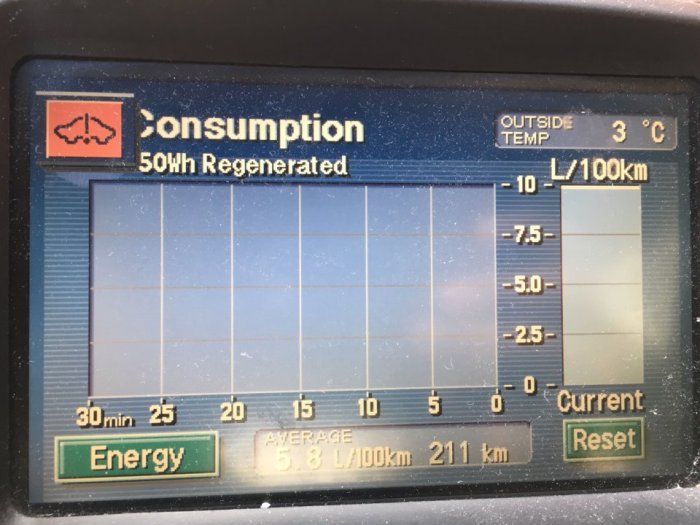

Case 2:A vehicle experienced poor fuel economy but had no powertrain DTCs. Using a scan tool, the technician monitored fuel trim values and found that the long-term fuel trim was consistently high, indicating a lean air-fuel mixture. Further investigation with a fuel pressure gauge revealed a clogged fuel filter.

Prevention and Maintenance

Preventing powertrain DTCs and freeze frame issues is crucial for maintaining optimal vehicle performance and longevity. Regular maintenance and proactive measures can significantly reduce the likelihood of these problems.

- Regular Oil Changes and Maintenance:Timely oil changes and proper maintenance, as per the manufacturer’s recommendations, ensure the engine and other powertrain components are well-lubricated and operating efficiently.

- Use of High-Quality Fuel:Using the recommended fuel grade and octane rating helps prevent engine knocking, premature wear, and the buildup of harmful deposits that can contribute to DTCs and freeze frames.

- Regular Vehicle Inspections:Periodic inspections by a qualified mechanic can identify potential issues early on, allowing for timely repairs and preventing more severe problems down the road.

Clarifying Questions: No Powertrain Dtcs Or Freeze

What are the potential causes of no powertrain DTCs or freeze?

This condition can arise from various factors, including faulty sensors, intermittent electrical issues, software glitches, or problems with the powertrain control module.

How can I troubleshoot no powertrain DTCs or freeze?

Begin by inspecting sensors, wiring, and connectors for damage or loose connections. Use a scan tool to monitor live data and perform actuator tests. Consider advanced diagnostic techniques such as waveform analysis or ECU reprogramming if necessary.

What are the benefits of preventing powertrain DTCs and freeze frame issues?

Preventing these issues enhances vehicle performance, reduces downtime, and promotes fuel efficiency. Regular maintenance, timely repairs, and using high-quality components contribute to a well-maintained powertrain system.